Quality Control Software for Manufacturing

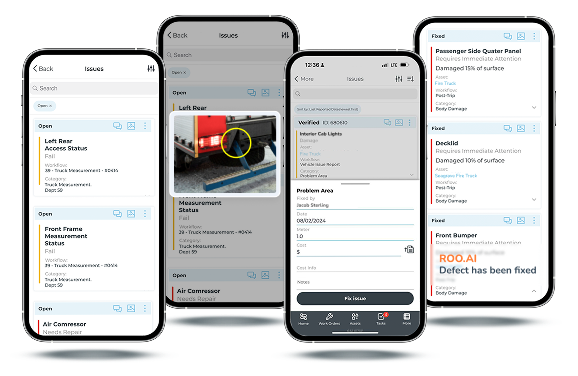

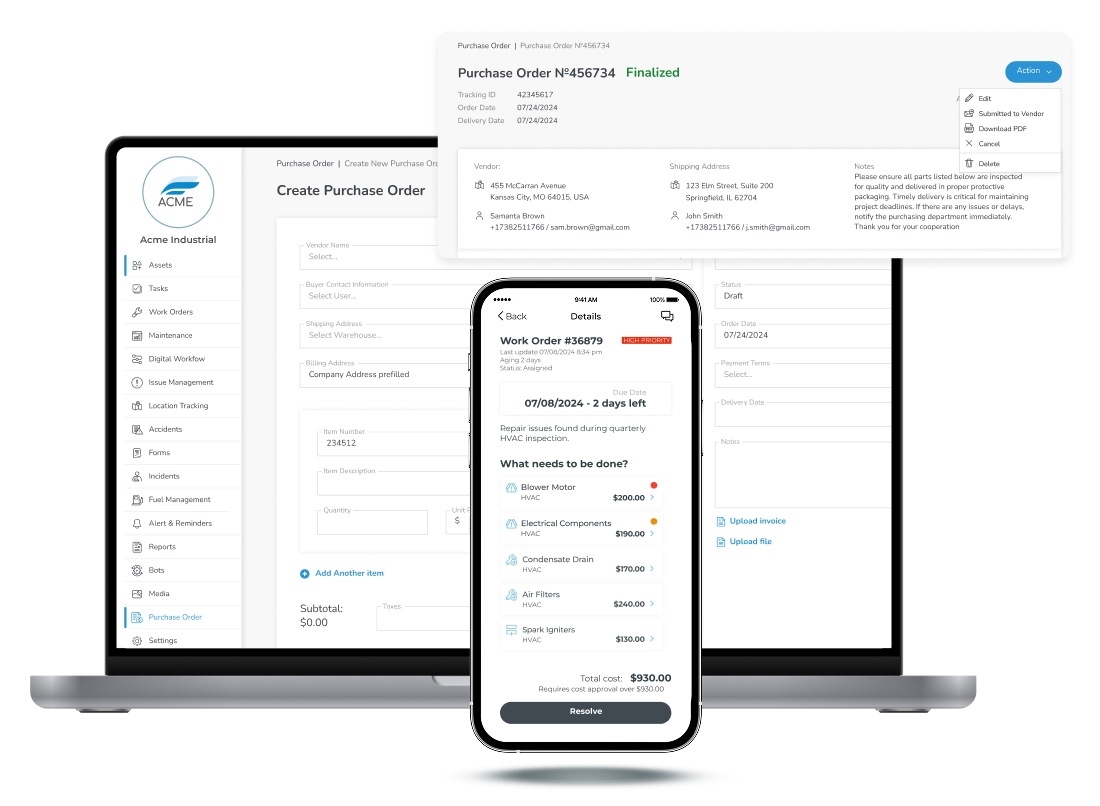

Faster, More Accurate Quality Inspections and Defect Resolution

Unique, visual inspections and LPAs cut time and improve defect detection, while providing instant visibility to deficiencies for faster corrective action by quality and production teams.

- In-Process, Incoming & Final Inspections (visual + guided)

- Closed-Loop CAPA & NCRs

(defect → repair → verify) - Parts/Lots/Serial Traceability & Audit-ready Records

- Embed Training, Photo/Video Evidence, QR Scan

Why are Quality Inspections Critical in Manufacturing?

Quality Inspections are structured checks (incoming, in-process, final) designed to ensure that materials, products, and processes meet defined requirements. Digital Quality Inspections, in particular, are a critical part of quality control (QC) and quality assurance (QA) programs, and QMS systems, because they automate the capture of defects with visual evidence and enable faster response with CAPA/NCRs while maintaining traceability - empowering teams to cut rework, reduce scrap, and boost customer satisfaction.

What Makes ROO.AI Quality Inspections Better

Powerful capabilities that transform your quality control process

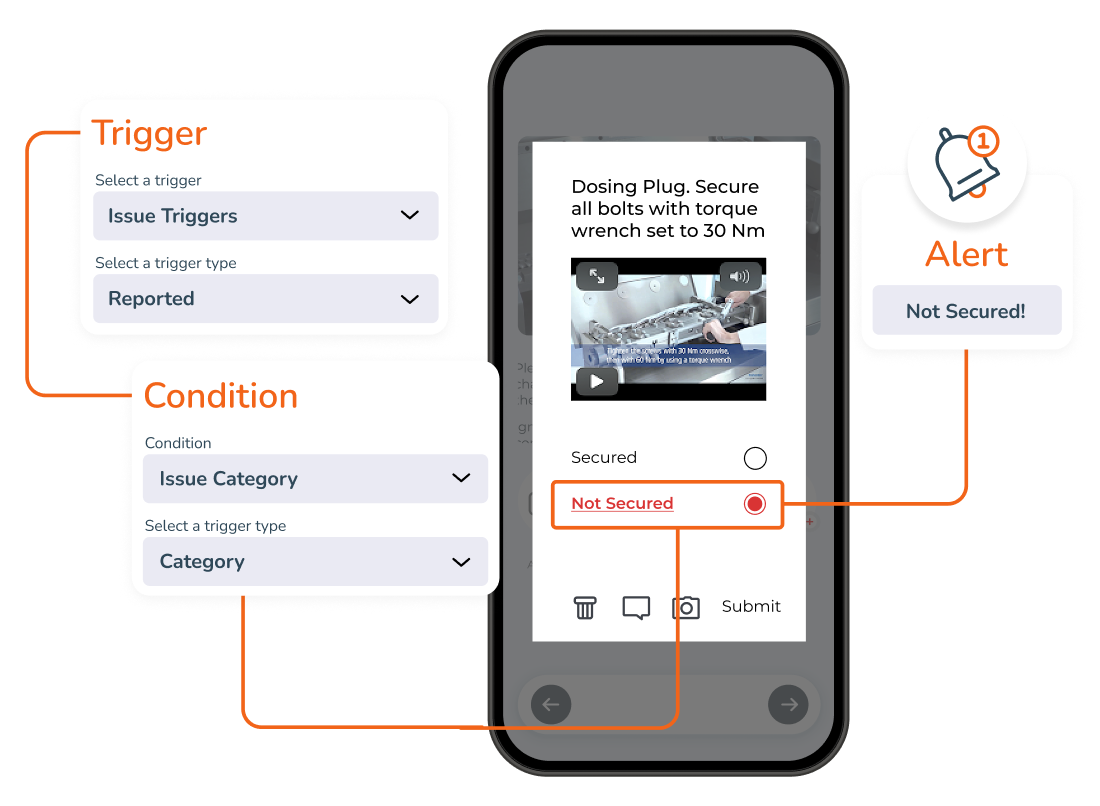

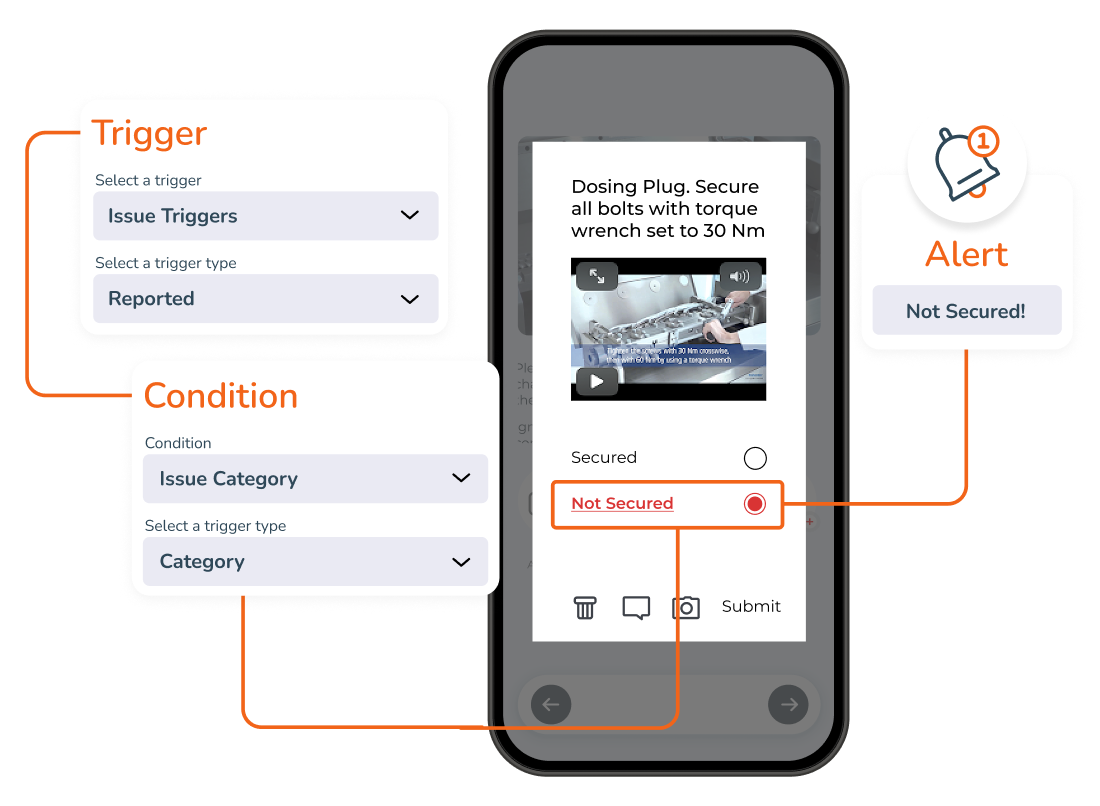

Visual Inspection Guidance

- Intuitive visual workflows

- Smart logic guides each step

- Embedded microlearning

- Smart Bots trigger alerts, actions

Faster, Operator Friendly

- One tap, swipe, group actions

- Forced proof, comments, diagnostics

- Fast multi-select, voice-to-text

- Offline support

Supplier & Incoming Quality

- Instant visibility to defects

- Assign fix & CAPA online

- Verify fix on the spot

- Open, Fix, Verify Dashboards

Traceability & Compliance

- Realtime KPIs: AQL, Scrap. Rework

- Automated history for every unit

- Supports ISO 9001 readiness

- Customized load & ship reports

Key Features for Smart Digital Quality Control

Replace paper checklists with an end-to-end digital quality platform to spot defects sooner, respond with fixes and CAPA faster, and automate NCR and traceability.

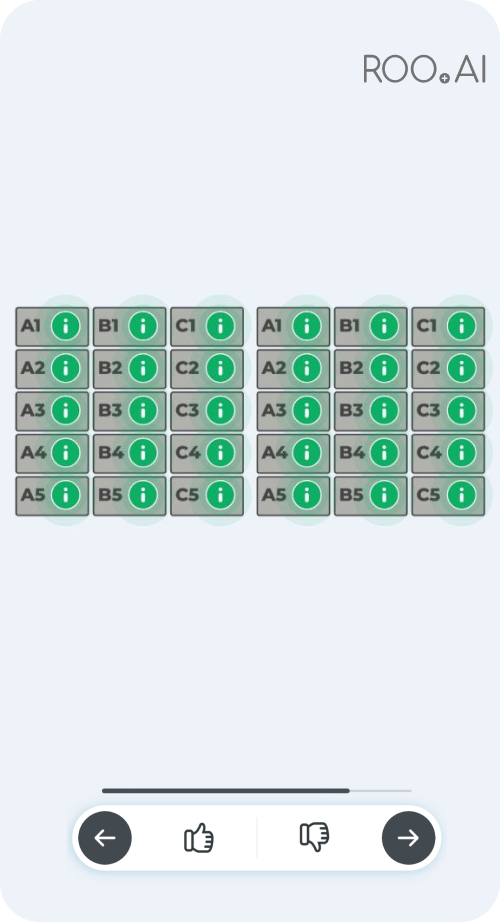

Faster Standardized Inspections

Intuitive Visual Inspection Workflows

- Inspection-specific visuals remove guesswork

- Voice to text notes, attach photos/videos

- Automatically map defect types and severity levels

- One tap, multi-select, swipe group boosts speed

Upskill, Onboard Faster

Smart Inspection Guidance

- Conditional logic guides operators step by step

- Inline SOPs & microtraining

- Automated alerts and notifications

- Finding trigger diagnostics and follow-ups

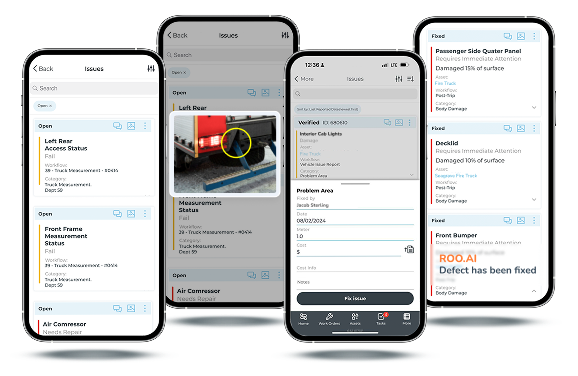

Faster Fixes & CAPA

Close the Loop from Defect to Verified Fix

- Defects instantly visible to managers & production

- Enable and record fixes on the spot

- Verify fixes on mobile; reopen if needed

- Automatically track defects & resolutions per unit

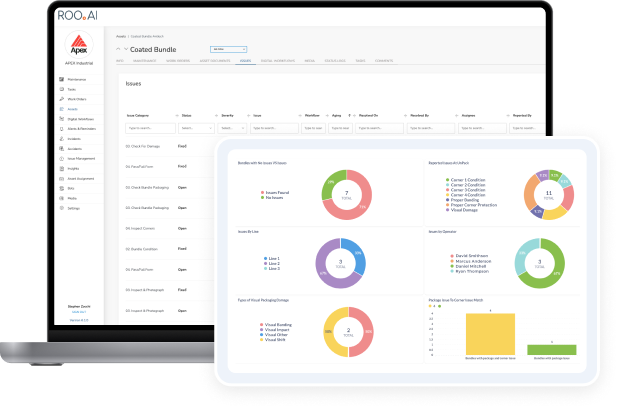

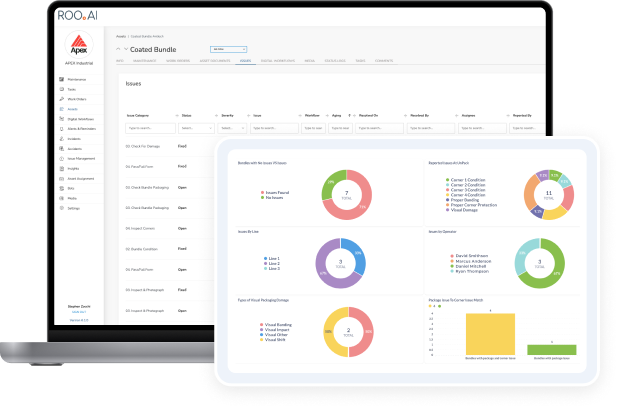

Gain Visibility, Reduce Paperwork

Automated Analysis, Traceability & Auditability

- Realtime dashboards - instant visibility to defects

- Monitor performance between lines, teams, and individuals

- Support documentation for audits: ISO 9001, IAFT 16949, GMP, HACCP

- Customized dashboards track KPIs: FPY, defect rates/types, scrap rates

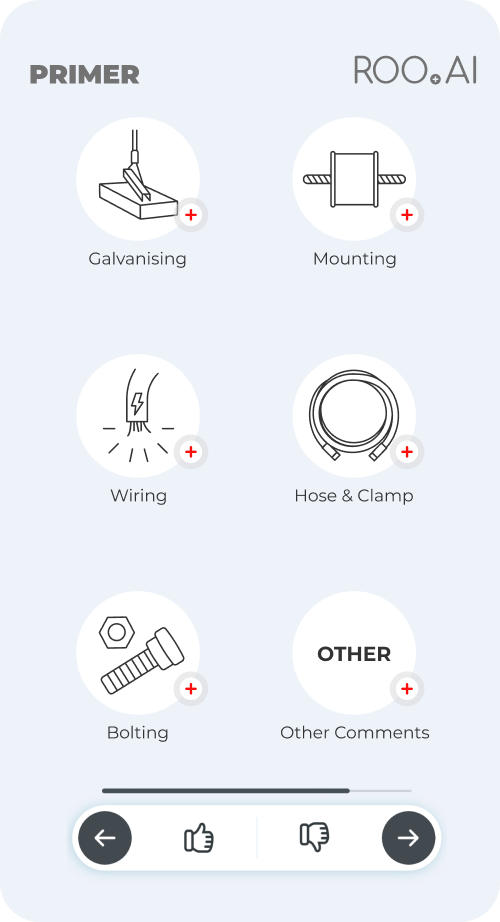

Supplier Quality (IQC)

In-Process Quality (IPQS)

Final & Pre-Shipment

Supplier Quality Control

- Support AQL/ANSI Z1.4 sampling tests

- Evidentiary documents for vendor NCR & correct actions

- Supplier scorecards and trends

- Automate receiving inspections

In-Process Quality Control

- Visually clear inspection points & criteria

- Built-in examples & training

- Defect visibility & alerts

- Enable operator self-verifications

Final & Pre-Shipment Quality

- Comprehensive final checklists

- Easy traceability, generation of tests records

- Load & ship visual proof

- Customer usable acceptance inspections

How It Works

Six simple steps to transform your quality control inspection process. No need to learn software, ROO.AI Concierge handles loading, set-up, and configurations.

Digitalize

Leverage existing checklists or spreadsheets, or define with ROO.AI team

Guide

Quality managers and operators follow visual, mobile flow with embedded SOPs

Detect

Defects are instantly visible online and categorized with details, images, and video

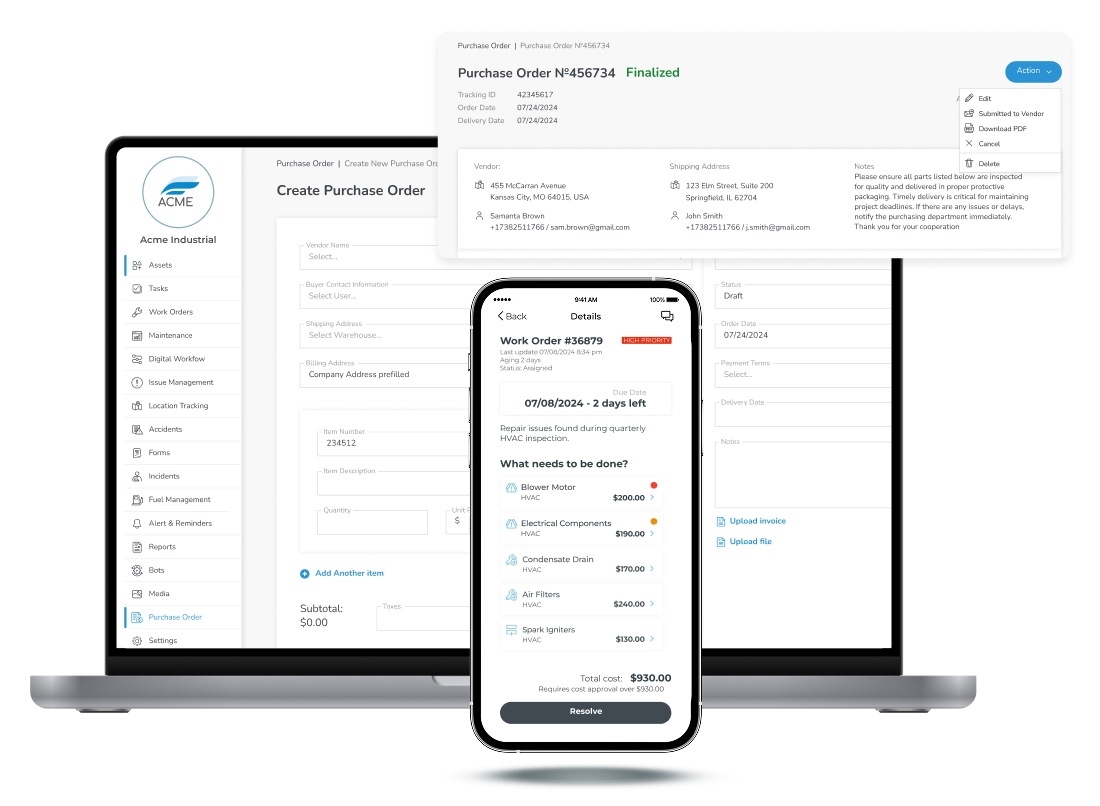

Resolve

Assign defects to work teams, document for NCRs/CAPA, and verify fixes

Trace

Audit-ready records—lots, stations, operators, timestamps

Improve

Dashboards for KPIs & Trends comparing lines, teams, individuals

Use AI to Digitalize Faster, Work Smarter

AI-powered rollout with minimal disruption

Quickly turn existing forms, checklists, and training videos into guided digital workflows. ROO.AI smart automations assist operators in-process with instructions and recommended fixes, boosting speed and quality without slowing production.

Rapid

Digitalization

In-Process Logic/ Bots/AI Assist

Continuous

Improvement & Traceability

- Convert paper/Excel/SOPs into mobile workflows fast

- Auto-extract steps from videos to create work instructions

- Embedded microlearning and in-flow guidance at every checkpoint

- In-process recommendations for defects and next-best actions

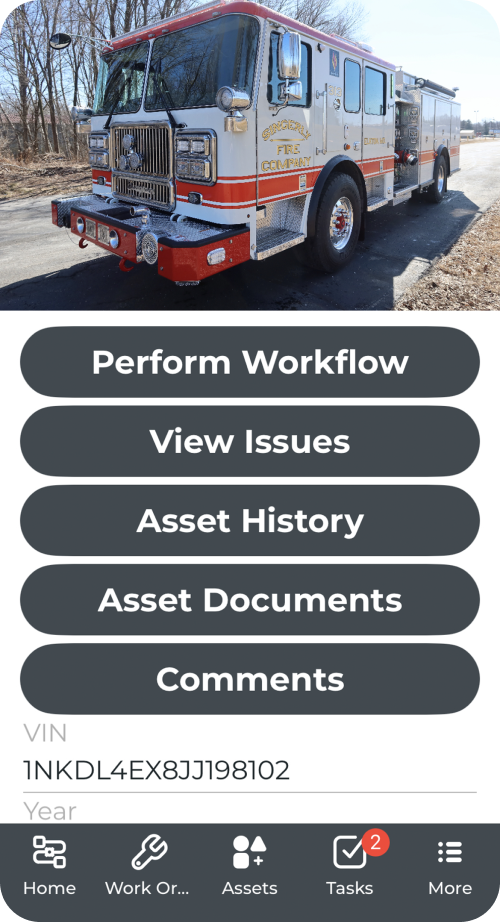

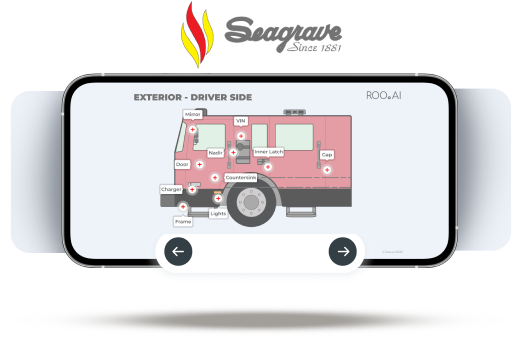

Quality Drives Industry's

Best Lifetime Value

As the oldest continuously operating manufacturer of fire apparatus, Seagrave Fire Apparatus has a reputation for delivering products with the industry’s best lifetime value. The company wanted to replace the paper capture of quality data and also automate the defect to repair process to drive both quality and productivity.

Built to Connect – ERP/MES/PLM/CMMS

Simplify sharing of critical data between systems to reduce duplicate data and possible data errors with ROO.AI's REST API and Web Hooks capabilities. Easily share data with corporate BI systems and align with company IT standards through SSO integration.

ERP Systems

MES Platforms

PLM Solutions

CMMS Tools

Outcomes & Benefits

Measurable results that drive quality, business value,

and competitive advantage.

Less Escaped Defects

Earlier detection reduces rework and scrap

Shorten

Production Cycles

A closed loop speeds up defect fixing in the verification process.

Audit-Ready

Automated records and reports cut prep time

Enables

Self Verification

Visual guidance, micro-training boost FTQ accountability

Lower COPQ

Measure and reduce scrap, rework, returns

100%

Reduction in visibility to defects

70%

Faster inspection completion

50%

Reduction in audit prep time

Frequently Asked Questions

Get answers to common questions about quality management software

What is digital quality inspection software?

How do digital quality inspections enhance a Quality Management System (QMS)?

What's the best software for quality inspections and defect resolutions?

How does Quality Inspection Software improve an overall QMS system for in-process defect management?

Can digital quality inspection software help with Supplier Quality?

How is traceability handled?

Does ROO.AI work offline?

With which quality standards does ROO.AI help manufacturers comply?

How fast can we deploy?

Can we add SPC and measurement data?

Ready to Transform Your Quality Management?

See ROO.AI in action with a personalized demo tailored to your manufacturing processes.